IN THE INDUSTRIAL FIELD, THE BLASTING IS AN INTERMEDIATE PROCESS IN CYCLE OF PRODUCT PROCESSING.

The removed layer can be oxide, slag, a galvanic or plastic coating, and so on. After this activity the material below the removed layer is completely uncovered and with a roughness depending on the dimension of the grit used in the process, but anyway very marked in comparison to normal values of machining.

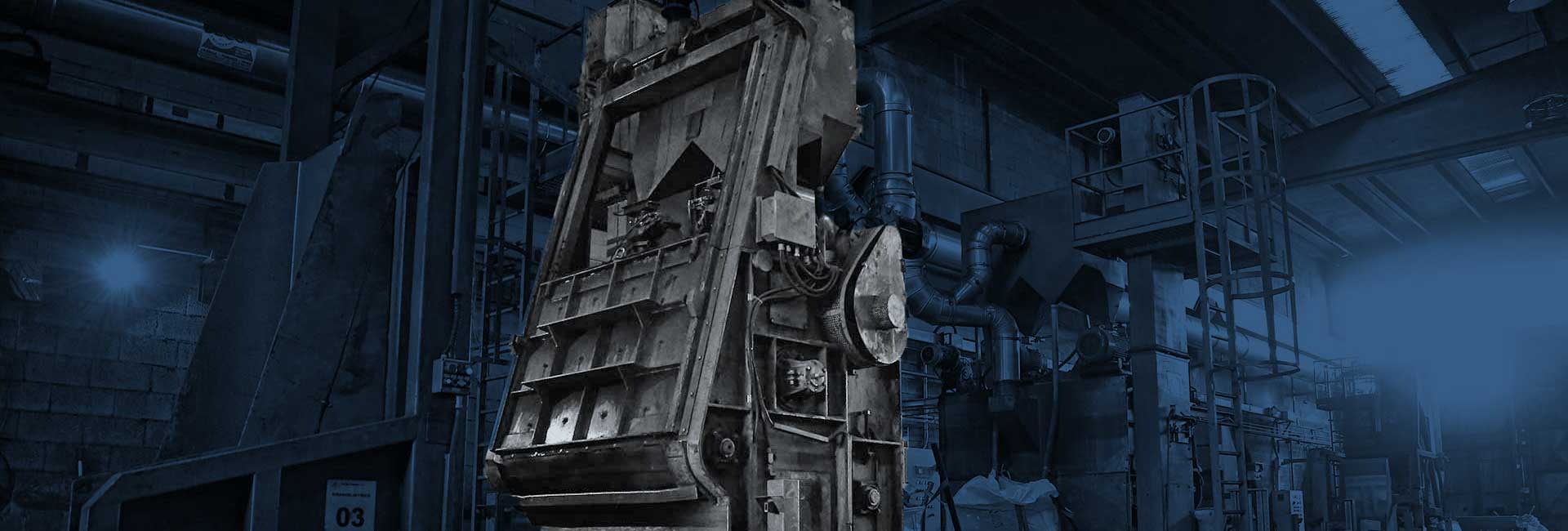

For all these reasons the industrial blasting is one of the most favorite activities to prepare the component for the following painting. The blasting is typically performed on steel, cast iron and light metallic alloys in general. The blasters are composed of a treadmill, which is bent in order to contain the components to be machined.

During the working cycle the components expose their whole surface to the abrasive action of the grit, which is thrown by one or more centrifugal turbines located on machine’s top. The combined effect of grit and tumbling makes the work very effective and quick.

Machines:

• Three blasters with steel treadmill up to 2000 kg

• A blaster with steel treadmill up to 3000 kg

• A blaster with rubber treadmill up to 400 kg